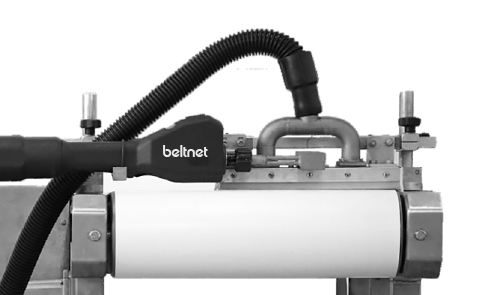

System for cleaning and disinfection of conveyor belts, by injecting saturated steam and simultaneous suction, leaving the belt dry after steam washing.

Eliminating the most persistent residues and disinfecting thanks to the 130ºC thermal shock.

The whole process is carried out while the belt is moving, resulting in a fast and automated cleaning process.

Comments are closed.